Know-how | Expertise | History | Environment

Every day, we are driven by the desire to deliver flawless craftsmanship.

our know-how

The Technical Design Office designs and collaborates closely with the workshop and all project stakeholders.

Storage of solid wood, naturally or vacuum-dried before being sawn.

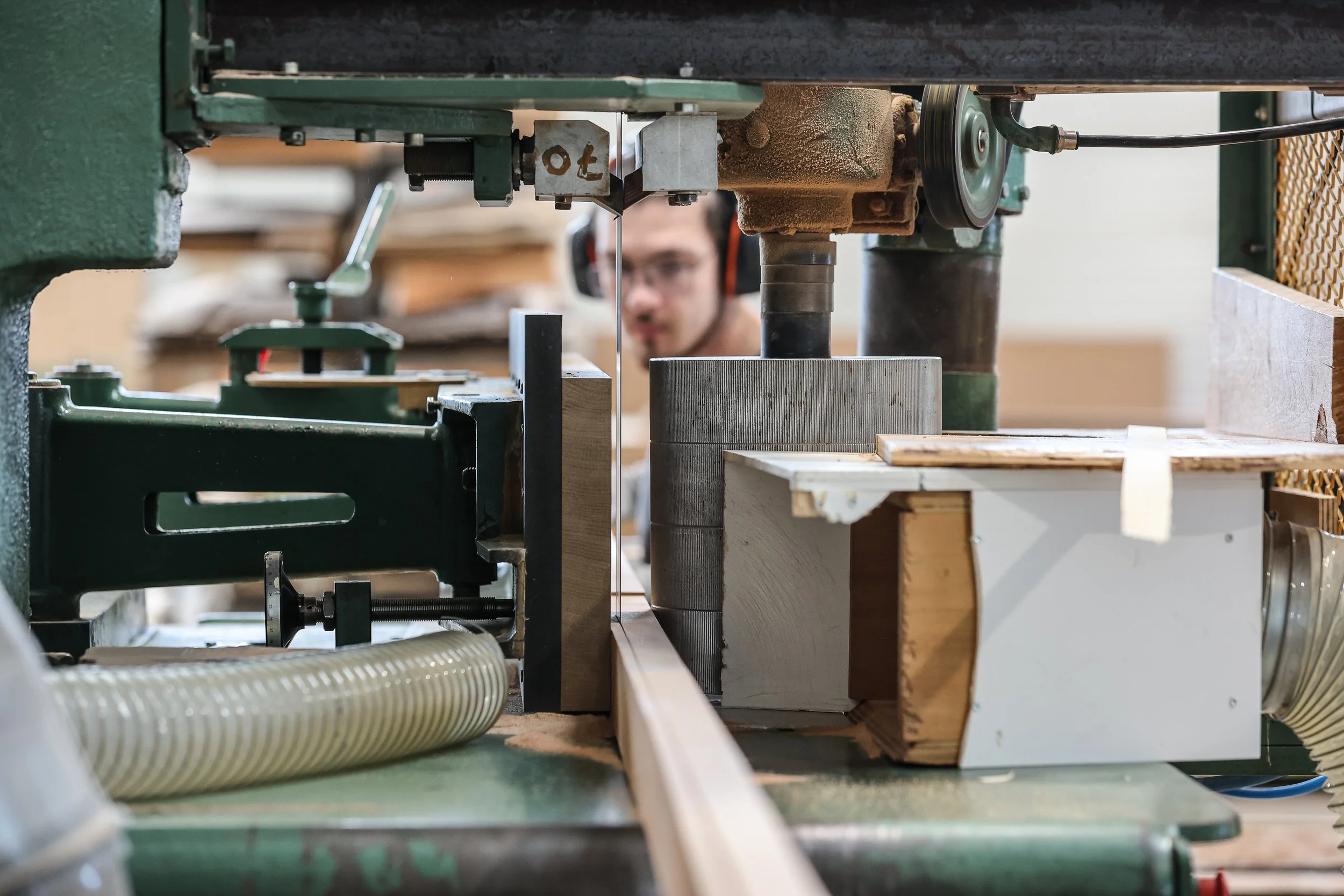

Manufacture of sawn veneers from solid wood.

Panel assembly of sawn veneers.

Machining with a 5-axis CNC machine

Oak panel gouged by CNC machining.

Customized veneer joints to match the aesthetics of each project

Handcrafted finishes such as gouge work.

Fine and controlled sandblasting technique.

Brushed finishing.

Spray-booth finishes: custom stains, varnishes, and lacquers.

Alabaster work.

Continuous quality control.

Installation in France and abroad.

Our expertise

Synthesis of integrated know-how :

Design office

Panel storage and throughput

Joinery and cabinetmaking

Storage of solid wood and veneers

Sawn veneer manufacturing

Veneer jointing & veneering.

3- and 5-axis CNC machining.

Sandblasting and soft abrasive blasting.

Finishes applied in spray booths (lacquer, stain, varnish).

Production of ISPM 15–compliant export crates.

Construction site setup and installation.

Alabaster handling and fabrication.

Resin workshop + Cold metallization

Leather and fabric sheathing

Fine metalwork (brass and aluminum)

"We believe that our policy of integrating know-how is the key to our expertise in serving our customers in the best possible way."

Guillaume Bordelongue, CEO

A look back at our history.

1896 - 1950: The beginnings

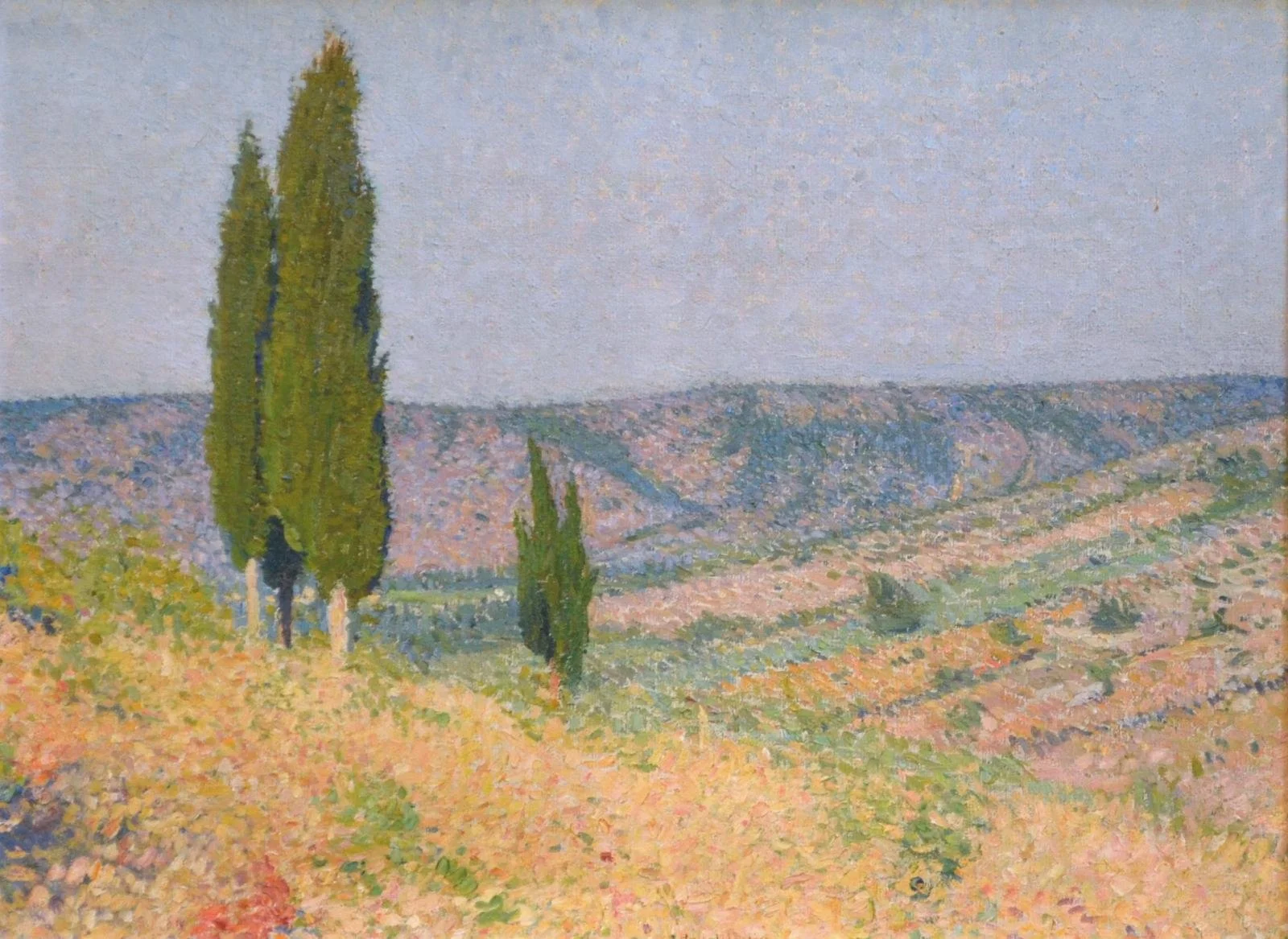

Founded in 1896 in Souillac in the Lot region, our workshop first made a name for itself by manufacturingtools for cabinetmakers and carpenters—planes, jack planes, mortise planes, and riflards—crafted from local woods such as service tree, beech, and holm oak, demonstrating a level of craftsmanship deeply rooted in the Quercy region.

Cypress landscape by Henri Martin.

Painted a few kilometers from our historic Souillac workshop

1951 - 1984: furniture and marquetry

With globalization, we are forced to abandon the manufacture of professional tools and return to the primary vocation of our artisans: cabinetmaking. Serving a local and then regional clientele, we create furniture and fittings for residential and boutique projects. Our mastery of marquetry has been particularly appreciated since the 1960s.

Marquetry of several wood species: ash, walnut, oak, ebony.

1985 - 2015: glulam and innovation

With Pierre and Brigitte Bordelongue buying the workshop in 1985, a culture of research and development transformed and expanded our team's expertise. Several innovations in laminated wood, the use of fiber optics, casting resins, and digital machining led us to file a number of patents.

During those years, our workshop was renamed Lamellux as a nod to the laminated-wood technique (lamellé-collé) and to our high-end positioning.

In 2009, the " Entreprise du Patrimoine Vivant " (EPV) label awarded by the French Ministry of the Economy, Industry and Employment confirms the excellence and rarity of our know-how.

Quertec® stool, Draped upholstery in smoked larch and backlit alabaster wall.

2015 - Today: continuity

Guillaume Bordelongue has been part of the team since 2007, and took over the family business in 2015. The family workshop continues to improve, with the construction of a new 3,500 m² workshop to be inaugurated in 2023 in Brive-La-Gaillarde, and the renewal of the machine park.

The team is strengthening its expertise in a range of areas (wood engineers, site managers, installers, etc.) in order to provide its clients with the best possible support for theirhigh-end interior design projects and to manage complex projects involving a combination of materials —wood, metal, marble, glass, textiles, leather, etc.

Multi-material layout: kitchen in travertine and patinated brass, custom upholstered bench seat with patinated brass skirting board, sandblasted spruce screen with integration of patinated brass bronze medal rushes.

close to nature

Our environmental commitment

At Lamellux, we believe that customization is the key to more responsible design.

Each project is thought out down to the smallest detail so that only what is necessary is used, without excess or waste.

It is this artisanal and precise approach that allows us to naturally reduce our environmental impact, while guaranteeing unique and sustainable creations.

Carefully selected materials

We make it a point of honor to select our wood according to the most demanding environmental standards, and we ensure that it is FSC certified.

Our solid wood species, particularly oak, come from French forests. We select the logs ourselves from suppliers to ensure both impeccable aesthetic quality and maximum optimization of the raw material.

Sustainable, waste-free production

Customization allows us to tailor our supplies precisely to each project, limiting waste right from the design stage.

In our workshops, nothing goes to waste: we reuse wood scraps to make supports, panels, or samples, and entrust the remaining scraps to a specialized partner responsible for recycling them.

This circular economy approach allows us to transform each step into a sustainable action.

Controlled and responsible processes

We pay particular attention to the quality and composition of the products used in our workshop.

We always choose the latest adhesives and finishes on the market, with some of the lowest VOC and formaldehyde levels available, in order to protect the health of our teams and our customers.

When adhesives require special treatment, they are disposed of in a safe and environmentally friendly manner.

Cleaning water is collected and treated by an approved company before being purified and returned to the municipal water system.

To ensure a healthy and safe working environment, our workshops are equipped with a state-of-the-art dust extraction system, guaranteeing clean air and a better quality of work for our teams.

In our finishing booths, a special device also captures and filters emissions, ensuring the safety and health of our employees while reducing releases into the atmosphere.

An eco-designed, forward-looking website

When constructing our new building, we incorporated current environmental standards and promoted sustainable transportation: easy access by bus, bicycle, or electric car, with charging stations available on site.